Application Success

CHOCOLATE MELTER

Make: Custom-made

Industry: Food & Beverage

Challenge

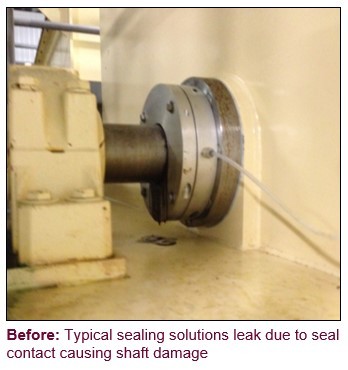

A large chocolate facility in Mexico, which exports 100% of their production to the United States, uses “melters” to keep chocolate in a liquid form to facilitate transportation while keeping the product uniform. The contact seals being used in the melters utilized air to press seal faces against the shaft. Over time, the seal faces would damage the shaft due to constant pressure, allowing chocolate to leak to atmosphere.

Solution

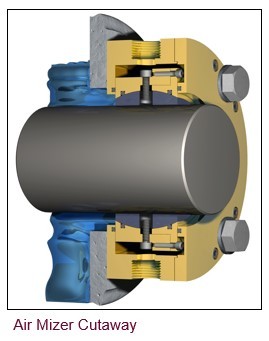

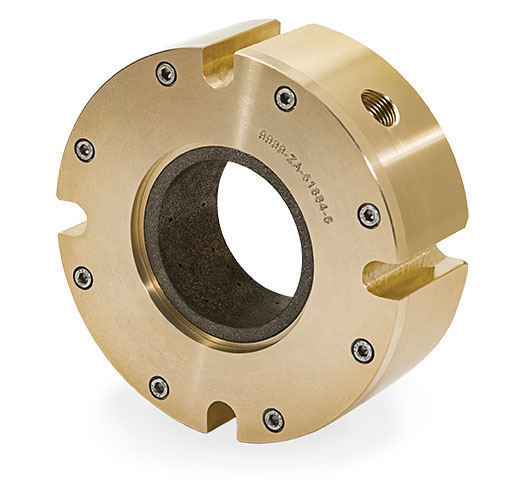

The melter was taken out of service in 2017 due to several issues, including shaft damage, deflection and bacteria growth caused by product leakage. A new melter, equipped with an Inpro/Seal® Air Mizer® shaft seal, was installed. The Inpro/Seal Air Mizer is a non-contacting shaft seal that utilizes a positive air purge along the shaft to permanently protect against product leakage or contamination. Its unique design fully articulates to accommodate angular, radial and axial shaft movement simultaneously. For this application, a Food Grade Air Mizer shaft seal was selected to meet FDA requirements.

Result

Since installation, the melter has run leak free, significantly saving the facility in housekeeping and lost product costs.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.