Application Success

ELECTRIC VEHICLE MOTOR

Type: Commercial Bus

Industry: Electric Vehicles

Challenge

An electric motor supplier for commercial buses was experiencing bearing damage due to ineffective shaft grounding from their current supplier of grounding brushes. They turned to Inpro/Seal, a leading provider of shaft grounding technology, for an effective solution.

Solution

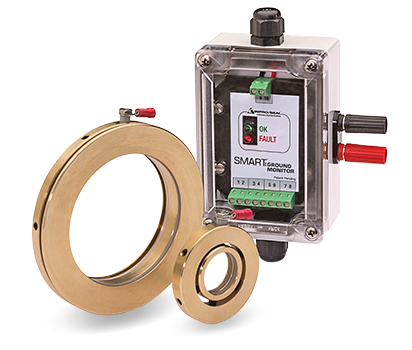

Inpro/Seal recommended their Current Diverter Ring (CDR), a maintenance-free shaft grounding solution that provides a low-impedance path to ground, diverting harmful shaft currents safely away from the motor bearings.

Result

Since switching to the CDR, the customer has not experienced bearing failure due to shaft current discharge on their motors installed in a variety of vehicles, resulting in significant benefits for the supplier, including increased motor reliability and reduced maintenance/warranty costs. The Inpro/Seal CDR has proven to be an effective solution for eliminating shaft current discharge and protecting motor bearings, showcasing its potential to benefit a wide range of commercial electric vehicle applications.

Inpro/Seal has extensive experience protecting against EDM on synchronous permanent magnet motor bearings for a variety of vehicle types, including:

- Commercial buses and trucks

- Construction equipment

- Agricultural equipment

- Lawncare equipment

- Forklifts and other lifting systems

- Municipal vehicles: fire trucks, police cars, garbage trucks

Proven Shaft Grounding Technology

npro/Seal offers several cost-effective solutions designed to protect against EDM, increasing motor and vehicle reliability.

The Inpro/Seal CDR (Current Diverter Ring) effectively diverts harmful shaft currents away from the bearings, directing them to ground. This prevents extreme bearing damage which causes vibration, noise and vehicle breakdown. Its proven design provides long-lasting protection for difficult-to-access electric motor bearings, offers a variety of mounting configurations and material options to fit the complexity of the vehicle design, and performs in wet or dry environments without impacting longevity.

For severe-duty environments, the robust design of the Inpro/Seal MGS (Motor Grounding Seal) combines shaft grounding capabilities with Bearing Isolator technology to eliminate lubrication leakage and bearing contamination.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.