Application Success

HORIZONTAL MIXER – ICING/FONDANT

Make: Gericke

Industry: Food and Beverage – Sugar

Challenge

A horizontal mixer was leaking product out of the vessel due to insufficient sealing. The lost product caused a safety issue and would be thrown out. To change the drive end seals the gearbox had to be removed and reinstalled, leading to two to three days of lost production each time. The leaking seals increased maintenance costs and downtime.

Solution

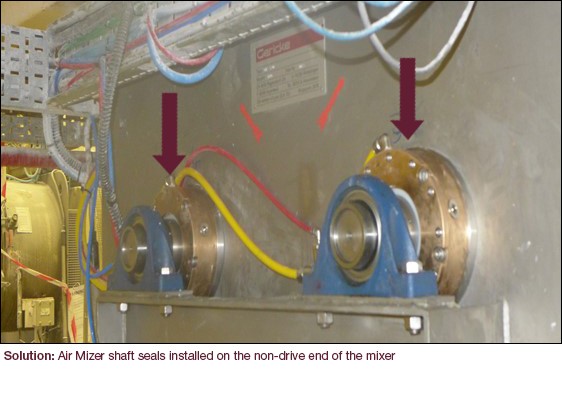

Inpro/Seal® Air Mizer® shaft seals were installed at both the drive end and non-drive end of the mixer. Two seals were needed per end for a total of four Air Mizer seal installs.

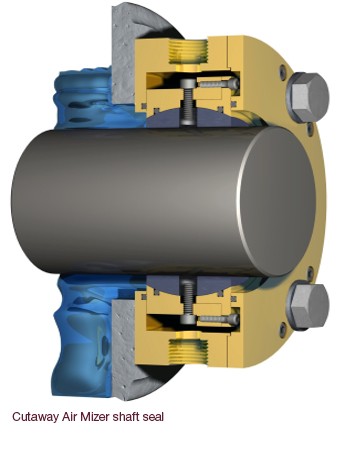

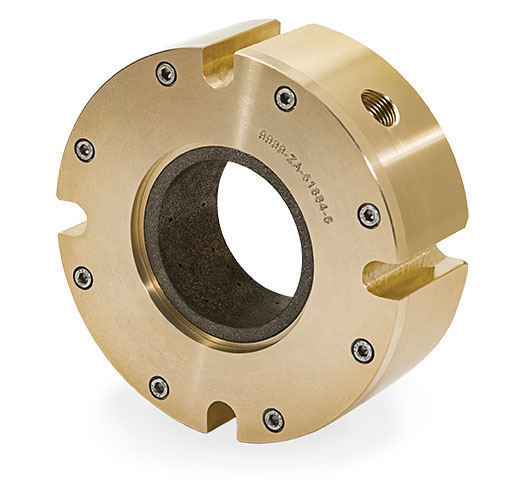

The Air Mizer is a maintenance free, fully articulating, non-contacting shaft seal that utilizes a positive air purge to eliminate product loss and contamination. Its unique design fully articulates to allow for radial, angular and axial shaft movement.

The Air Mizer seals were constructed of food grade materials to accommodate industry regulations and were ATEX certified due to the hazardous environment. A unique challenge for this application was that the seals required a consistent sealing pressure, as any abnormal pressure spikes would trigger the explosion arresting system.

Result

The Air Mizer seals were installed in 2012. Following a 100% maintenance/leak free period of 14 months, a second mixer was also upgraded. All Air Mizer seals are operating as designed, maintenance free with zero leakage.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.