Application Success

PAPER MACHINE ROLL

Industry: Pulp & Paper

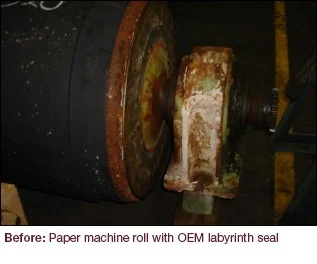

Challenge

The OEM solution, a simple labyrinth seal, allowed water ingress into the bearing. Due to premature bearing failure from water contamination, the customer could not get life out of the roll cover or bearings. This lead to high maintenance costs, interruption in production due to equipment downtime and safety risks.

Solution

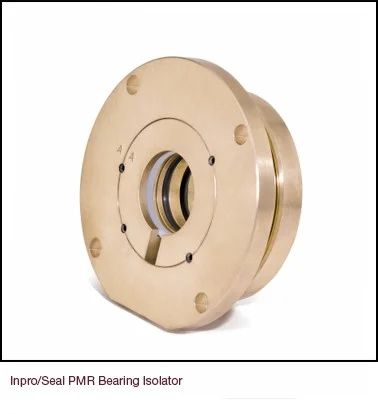

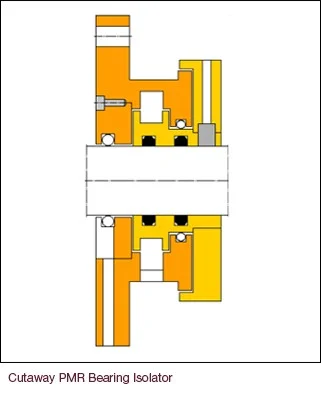

The OEM labyrinth seal was machined off and a flanged Inpro/Seal® PMR (Paper Machine Roll) Bearing Isolator was installed. Inpro/Seal Bearing Isolators are non-contacting compound labyrinth seals that permanently protect against contamination ingress and lubrication loss.

Result

The first PMR Bearing Isolator was installed on a paper machine roll in 2016 and has exceeded customer expectations. Since then, the mill continually replaces all OEM labyrinth seals with Inpro/Seal PMR Bearing Isolators on every roll rebuild.

Permanent Bearing Protection

Inpro/Seal Bearing Isolators provide permanent bearing protection against contamination ingress and lubrication loss on rotating equipment. With a unique, non-contacting design, Inpro/Seal Bearing Isolators are maintenance-free and last lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.