Case Study

Air Mizer® Shaft Seals Upgrade Stops Costs and Product Loss from Piling Up

Application: Pancake Mixers

For a mixer that processes 15,000 lbs. of dry mix every hour, a leaking seal that requires replacement every six months is costly. These high costs include lost product, extensive maintenance, increased downtime and safety hazards. Multiply these losses by 10 mixers, each operating three shifts a day, five days a week, and the accumulated losses become unsustainable.

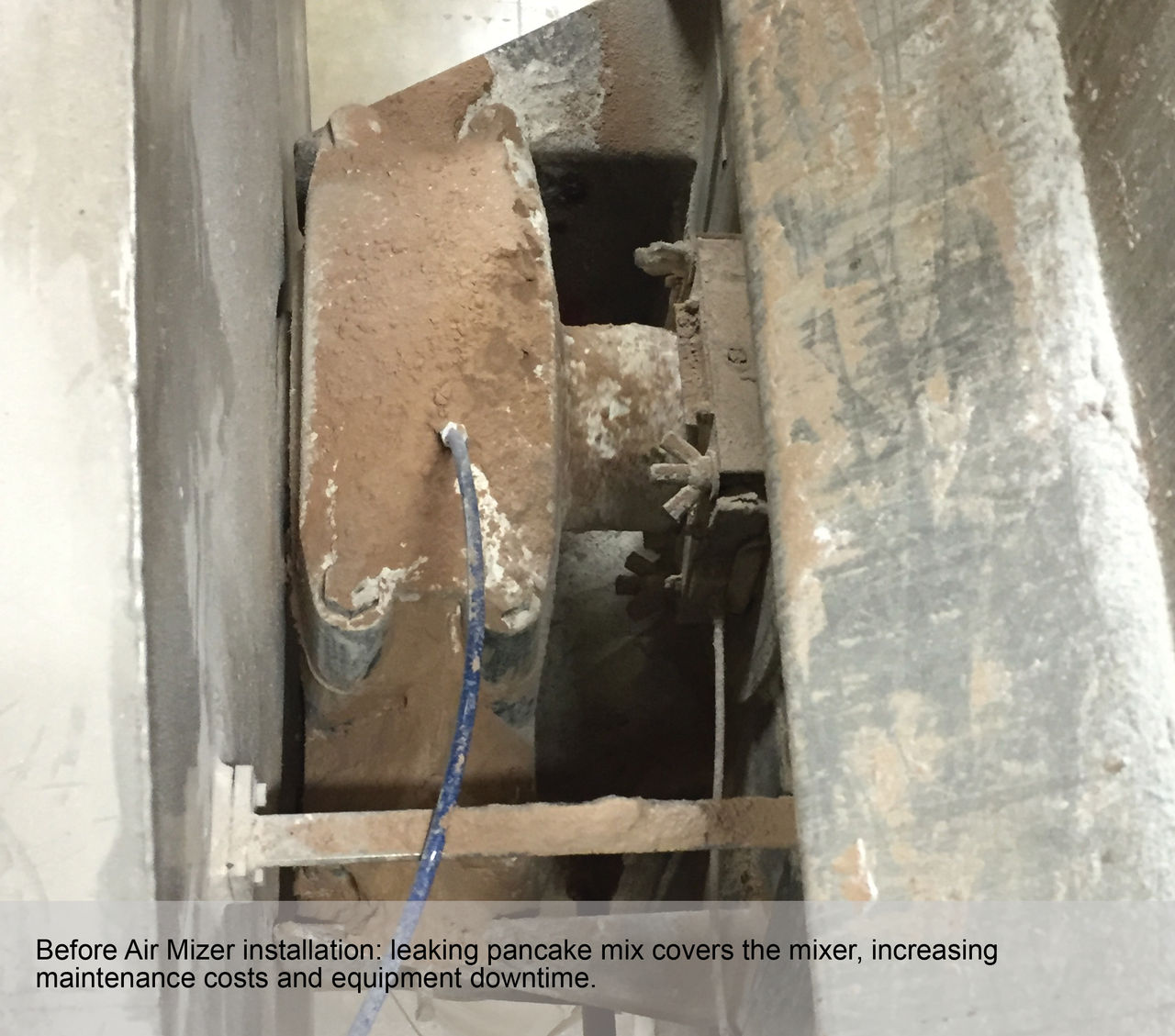

At a food manufacturing facility in Ohio, leaking mixers were losing 830 lbs. (415 boxes) of pancake mix every week. The facility uses mixers that have six CO2 lines for cooling the hot oil that enters the mixer as well as preventing the chocolate chips from melting. After six months of operation, the mixer’s original seals would start leaking the dry pancake mix and would need to be replaced. An equipment analysis determined that the contact seals failed because they could not accommodate the shaft-to-bore misalignment (STBM) with tight clearances. Over a short time, wear on the seal faces caused a gap that allowed product to escape making the contact seal ineffective.

Maintenance Cost Pile Up

Maintenance associated with the leaks added up. Each day, on each of the three shifts, plant personnel spent 20 minutes cleaning up the leaking dry mix, totaling five extra maintenance hours per week. All the leaked dry mix had to be thrown out, increasing product costs. Two team members spent eight hours on each mixer replacing the seals every six months. Each seal replacement cost approximately $6,000. Over the year, the failing seals created 290 man hours of work; 160 were also lost production hours. Additional production time was lost when conveyors shut down due to the leaking dry mix dust falling below the mixer and accumulating on the conveyor sensors.

The manufacturing plant sought a more durable solution for their mixers. They turned to Ivanne Spooner, a Technical Salesperson for Galloup and local distributor for Inpro/Seal® custom-engineered bearing protection and process seals. Ivanne suggested Inpro/Seal Air Mizer shaft seals, which can handle STBM and shaft angularity to the housing face. Given the seals’ ability to handle extreme amounts of shaft movement and the proven success of Air Mizer shaft seals in sealing the plant’s sugar conveyors, they decided to move forward with the upgrade.

Eliminate Leakage with an Air Seal

Inpro/Seal Air Mizer shaft seals seal against product loss, and contamination by directing a small amount of air through a precision clearance between the seal and the shaft, pressurizing the clearance. The air is directed toward the product and atmosphere equally.

To seal the mixers, plant air was delivered to the seal at 13 psi. By using plant air, the seal avoids additional operating expenses.

Air Mizer shaft seals can fully articulate to accommodate radial run-out, axial movement, and angular misalignment simultaneously – making this the perfect solution for the mixers. As non-contacting seals, Air Mizer shaft seals are designed to last the lifetime of the mixer.

The food manufacturing plant chose a split Food Grade design. The Food Grade design is constructed of FDA-approved materials and elastomers for use in food processing facilities and the split design allows for easy installation.

Success Summary

Since September 2014, Air Mizer shaft seals have been installed on six of the facility’s 10 mixers. After two years, they had not experienced any degradation of seal performance. Air Mizer shaft seals are saving the plant $18,750 per mixer each year; that’s $112,500 across the six mixers installed with Air Mizer shaft seals. The last four mixers are due to have Air Mizer shaft seals installed as well.

Advantages of Air Mizer Shaft Seals on Mixers

- Permanently protect against product loss and harmful emissions.

- Accommodate high levels of shaft deflection and misalignment.

- Can be constructed of FDA-approved materials for use in the food industry.

- Can be split for easy installation without de-coupling equipment.

- Are maintenance-free and will last the lifetime of the applications.

- Decreases high maintenance costs.

Ready to Get Started?

Count on us to improve equipment reliability and process efficiency with complete shaft sealing solutions. Our experienced sales and engineering team can design a custom engineered shaft seal to fit the exact requirements of your equipment and operating environment.