Case Study

Current Diverter Ring® Extends the Life of Energy-Efficient HVAC Equipment

Application: Chiller Pumps

A leading plastic injection company planned to install variable frequency drives (VFDs) on their chiller pumps to increase energy efficiency and reduce operating costs. These drives are increasingly popular in the HVAC industry because of their ability to economically meet changing load demands.

While the use of VFD systems provides many benefits, the company was concerned because VFDs have been known to cause premature system failure. VFDs induce high frequency voltages that build on the shaft until they discharge to ground through the motor’s bearings and the bearings of coupled equipment. Over time, these discharges cause premature bearing failure.

A Complete Shaft Grounding Solution

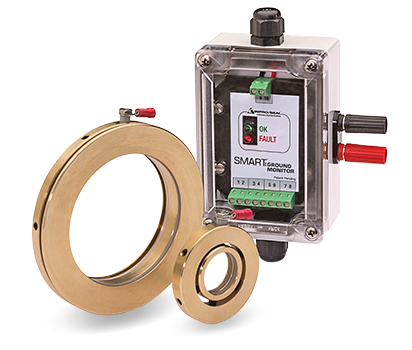

The customer specified to their vendor of choice, Gardiner Trane, a full-service HVAC energy solutions provider, that bearing protection be added to the VFD installation project to safeguard their investment. Gardiner Trane chose the Inpro/Seal Current Diverter Ring (CDR®) as their complete shaft grounding solution. The CDR utilizes proprietary conductive filaments to divert harmful shaft currents away from the bearings and to ground.

“Originally we were going to use a complete ring assembly,” said William Thompson of Gardiner Trane, “but after consulting Inpro/Seal’s application engineers, they recommended a split design for easy installation.”

Thompson explained that Inpro/Seal’s ability to custom engineer a split design CDR for each piece of equipment was an attractive feature to Gardiner Trane because of shaft diameter variations on their customer’s motors. “The pumps are close coupled and getting the correct measurement was difficult,” he said. “Getting the size right was critically important.”

Quick Delivery, Easy Installation

Nineteen custom-engineered CDRs were delivered to Gardiner Trane in one to two days. Gardiner Trane installed them on Sundays so that the installation process wouldn’t interrupt the customer’s production schedule. “Inpro/Seal’s sales engineer guided us through the installation process,” Thompson said.

Return on Investment

Since the CDR devices were installed, Gardiner Trane and their customer have observed no evidence of bearing damage. Thanks to the bearing protection Inpro/Seal provides, the customer is able to enjoy all the energy efficiency and cost saving benefits that VFDs offer without fear of premature bearing wear, motor failure, or expensive downtime.

Thompson stated, “We service this customer with an ongoing agreement for their HVAC equipment and assist with the operation of the pump skids if needed. Since we installed the CDR devices there have not been any issues – the original bearings are still operating with the new VFDs.”

Shaft Grounding Solutions

Inpro/Seal Shaft Grounding effectively diverts harmful shaft currents away from the bearings to ground, increasing bearing and equipment reliability.

Our Current Diverter Ring uses proprietary conductive filaments to provide shaft currents a low impedance path to ground, with a zero maintenance design.

Ready to Get Started?

Count on us to improve VFD-driven equipment reliability by diverting harmful shaft currents to ground, away from the bearings. Inpro/Seal Shaft Grounding solutions combine proven technology with innovative features to ensure superior bearing protection.