Application Success

BUCKET ELEVATOR

Seal Position: Head Shaft

Industry: Pulp & Paper

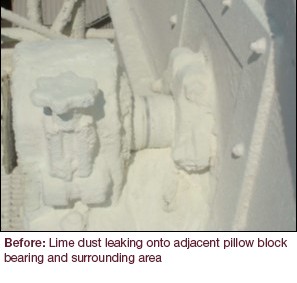

Challenge

Excessive lime dust leakage from the OEM head shaft seals contaminated the adjacent pillow block bearing and surrounding process area. The OEM sealing method was a braided compression packing. Due to the nature of the product, and the inability to provide any type of flush, the compression packing required constant maintenance and would need to be replaced every three months.

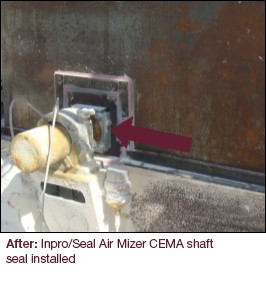

Solution

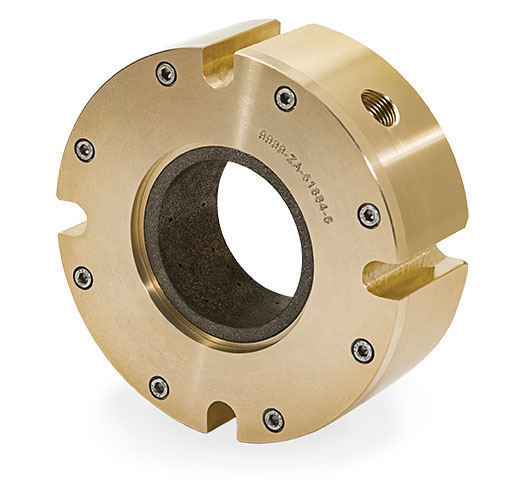

An Inpro/Seal® Air Mizer® CEMA shaft seal was installed. The Air Mizer CEMA is a non-contacting, non-wearing shaft seal specifically for CEMA designed conveying equipment. Its unique design utilizes a positive air purge to permanently eliminate product leakage.

Result

The Air Mizer CEMA shaft seals were installed in 2011 and performance has been outstanding with zero maintenance issues. Replacement seals were ordered in 2020.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.