Application Success

RIBBON BLENDER

Make: Custom Built Ribbon Blender

Industry: Food and Beverage

Challenge

On a custom ribbon blender blending flour recipes for the tortilla and masa flour market, the customer was constantly replacing rope packing within the air purged stuffing box. Air was pumped into the packing stuffing box to try and push back against the flour making its way out of the trough. Flour would eventually leak out and pile up against the pillow block and onto the floor, making a huge mess.

This caused safety concerns and increased maintenance costs by adding extra overtime hours to clean up the mess. The product that leaked out of the vessel would have to be thrown out, causing significant product loss.

Solution

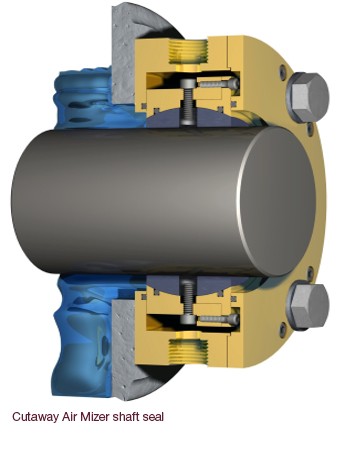

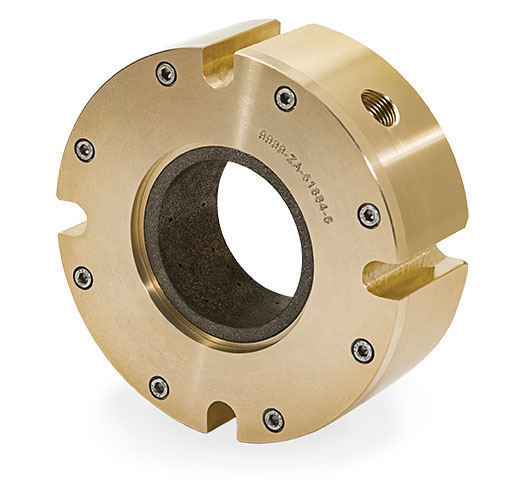

An Inpro/Seal® Air Mizer® Food Grade shaft seal was installed at both the drive-end and non-drive-end on a single mixer in 2019. The Inpro/Seal Air Mizer is a non-contacting, non-wearing permanent shaft seal that permanently protects against product loss and contamination. Its unique design fully articulates to handle angular, radial and axial shaft movement simultaneously.

Result

Since the mixer was upgraded with Air Mizer shaft seals, they have had no issues. The customer is extremely happy with the change.

Maintenance-Free Shaft Sealing

Inpro/Seal Air Mizer shaft seals provide permanent protection against product loss and contamination on industrial process equipment. With a unique, non-wearing design, Air Mizer seals are maintenance-free and constructed to last the lifetime of your equipment.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.