Application Success

PROCESS STEAM TURBINE

Make: Dresser Rand

Model: DR353

Industry: Oil & Gas

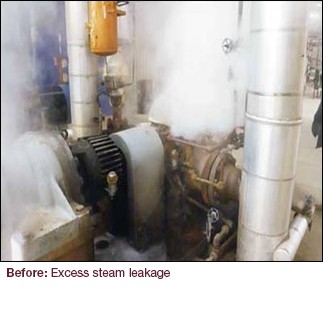

Challenge

Excessive steam leakage on a DR353 Dresser Rand process steam turbine caused by carbon ring wear lead to rust in the gland box, accelerated wear, and premature bearing failure due to ingress of condensate in the bearing housing.

Solution

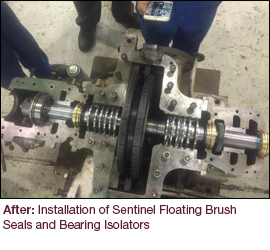

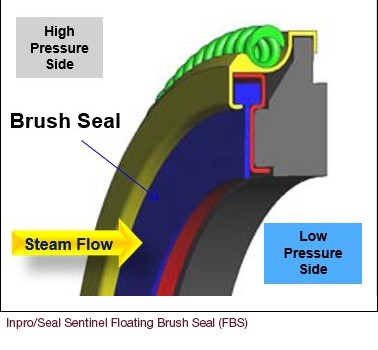

The operator replaced two upstream carbon rings on each side of the exhaust and steam ends with Inpro/Seal® Sentinel® Floating Brush Seals (FBS). The Sentinel FBS is designed as a drop in replacement for existing carbon rings so rotor removal is not always necessary and only minimum housing modifications may be required for location of the anti-rotation pin.

Bearing protection was further enhanced by installing Inpro/Seal Steam Turbine Bearing Isolators, which protect the bearings from steam leakage entering the bearing housing.

Result

Steam leakage was dramatically reduced, increasing mean time between repair (MTBR), reducing maintenance costs and improving health and safety.

The seals have been running trouble free for more than four years. The customer has since upgraded four more of their DR353 turbines.

Increase Steam Turbine Efficiency

The Inpro/Seal Sentinel Floating Brush Seal reduces steam turbine maintenance and steam loss by providing an extra layer of protection for process steam turbines.

Ready to Get Started?

Count on us to improve reliability and process efficiency within your facility. Our experienced sales and engineering team can design custom engineered bearing protection or shaft sealing solutions to fit the exact requirements of your equipment and operating environment.